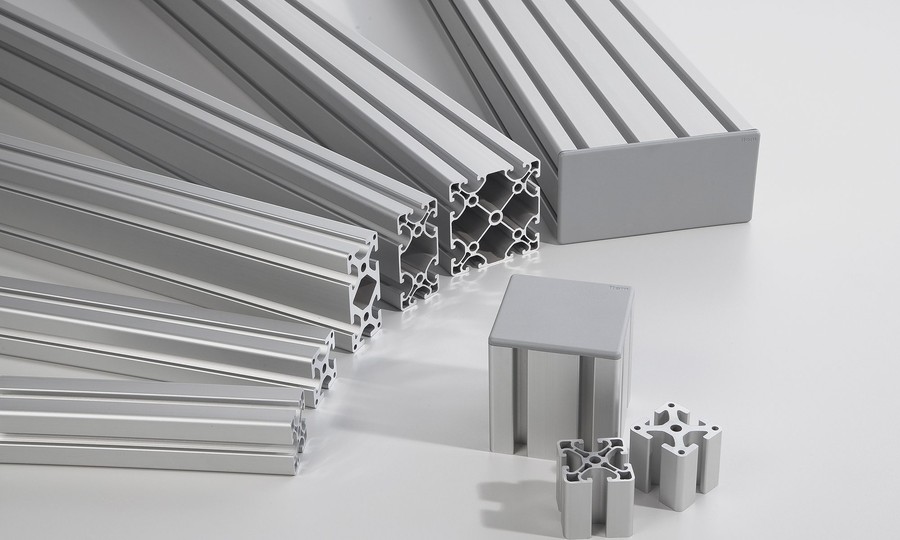

The panorama of aluminium profiling continues to adapt at an unparalleled tempo, pushed by way of technological development, converting marketplace calls for, and the relentless pursuit of producing excellence. These days’s inventions in aluminium profiling constitute a convergence of fabrics science, complicated production applied sciences, and virtual transformation this is reshaping how we means design, manufacturing, and alertness of extruded aluminium elements.

Subsequent-Era Production Applied sciences

The mixing of Business 4.0 applied sciences into aluminium profiling operations has essentially reworked conventional production paradigms. Good production methods now make the most of interconnected sensors, complicated analytics, and device studying algorithms to optimize manufacturing processes in real-time, attaining ranges of potency and high quality that have been up to now inconceivable.

Predictive upkeep methods observe apparatus efficiency ceaselessly, figuring out doable problems prior to they have an effect on manufacturing. Those methods analyze vibration patterns, temperature permutations, and different operational parameters to time table upkeep actions proactively, minimizing unplanned downtime whilst optimizing apparatus lifestyles cycles.

Complicated task modeling and simulation applied sciences allow digital optimization of extrusion parameters prior to bodily manufacturing starts. Those virtual gear can expect subject material glide patterns, establish doable defects, and optimize die designs to succeed in awesome effects whilst minimizing construction time and prices.

Progressive Alloy Building

Fabrics science inventions are increasing the efficiency envelope of aluminium profiling via construction of specialised alloys adapted for particular packages. Complicated alloy compositions incorporate hint parts that fortify particular homes comparable to corrosion resistance, thermal conductivity, or mechanical energy with out compromising extrudability.

Nanostructured aluminium alloys constitute a frontier era that contains nanoscale reinforcement debris to succeed in outstanding energy and stiffness traits. Those complicated fabrics allow the advent of ultra-lightweight profiles with efficiency traits coming near the ones of a lot heavier conventional fabrics.

Functionally graded fabrics constitute every other innovation frontier, the place alloy composition varies throughout profile cross-sections to optimize homes for particular loading stipulations. This means allows unparalleled optimization of subject material distribution and function traits inside unmarried extruded profiles.

Virtual Design and Simulation Equipment

Laptop-aided design and simulation applied sciences have revolutionized the aluminium profiling construction task. Complicated finite part research gear allow exact prediction of structural efficiency, thermal conduct, and failure modes prior to bodily prototyping starts.

Generative design algorithms can routinely optimize profile geometries for particular efficiency standards, exploring design areas that will be impractical for guide optimization. Those gear frequently establish leading edge answers that mix awesome efficiency with progressed manufacturability.

Virtual dual applied sciences create digital representations of extrusion processes that allow real-time optimization and predictive high quality regulate. Those methods ceaselessly be told from manufacturing information to beef up task regulate and expect high quality results with outstanding accuracy.

Additive Production Integration

The convergence of additive production with conventional extrusion processes is growing new chances for complicated, multi-functional elements. Hybrid production approaches mix the potency of extrusion for elementary profiles with the design freedom of additive production for complicated options.

3-d-printed die inserts allow fast prototyping of recent profile designs with out the time and value related to conventional die production. This capacity speeds up construction cycles and allows cost-effective exploration of design choices.

Built-in post-processing the use of additive production can upload complicated options to extruded profiles that will be unimaginable to succeed in via standard production strategies. This means combines the industrial benefits of extrusion with the design flexibility of additive production.

Floor Engineering Inventions

Complicated floor remedy applied sciences are increasing the purposeful functions of aluminium profiles past conventional packages. Plasma-enhanced coating processes allow the appliance of specialised floor layers that offer enhanced corrosion resistance, progressed put on traits, or specialised purposeful homes.

Nano-coating applied sciences create ultra-thin floor layers with exactly managed homes. Those coatings may give hydrophobic or hydrophilic surfaces, enhanced thermal control traits, or specialised optical homes whilst keeping up the underlying mechanical homes of the aluminium substrate.

Built-in floor texturing right through the extrusion task can create profiles with optimized floor traits for particular packages. This means removes separate floor remedy operations whilst offering awesome efficiency traits in comparison to post-process texturing strategies.

Automation and Robotics Integration

Complicated automation methods are remodeling aluminium profiling operations from subject material dealing with via ultimate inspection and packaging. Robot methods supply constant dealing with of profiles whilst getting rid of doable for harm right through processing and decreasing hard work necessities.

Computerized high quality inspection methods make the most of device imaginative and prescient and complicated sensors to ensure dimensional accuracy, floor high quality, and different essential traits at manufacturing speeds. Those methods supply complete high quality documentation whilst figuring out defects that could be overlooked by way of conventional inspection strategies.

Clever subject material dealing with methods optimize workflow during profiling operations, decreasing dealing with time whilst keeping up cautious regulate of profile situation. Those methods frequently combine with endeavor useful resource making plans methods to supply real-time manufacturing visibility and stock control.

Sustainable Innovation Practices

Environmental issues proceed to pressure innovation in aluminium profiling, with new applied sciences taken with decreasing power intake, minimizing waste, and making improvements to recyclability. Complicated furnace designs succeed in upper thermal potency whilst decreasing emissions and effort intake.

Closed-loop recycling methods allow direct reprocessing of manufacturing scrap with out exterior recycling operations. Those methods deal with subject material high quality whilst decreasing transportation necessities and making improvements to total sustainability metrics.

For producers in the hunt for get entry to to the newest inventions in aluminium profiling, partnering with forward-thinking providers like Aluminium Profile supplies get entry to to state of the art applied sciences and construction functions that strengthen leading edge product construction and aggressive merit.

Synthetic Intelligence Programs

Device studying algorithms are being deployed during aluminium profiling operations to optimize task parameters, expect high quality results, and establish development alternatives. Those methods ceaselessly be told from manufacturing information to beef up efficiency over the years.

Laptop imaginative and prescient methods powered by way of synthetic intelligence can locate floor defects, dimensional permutations, and different high quality problems with larger accuracy and consistency than conventional inspection strategies. Those methods additionally supply treasured information for task optimization and steady development tasks.

Predictive analytics allow proactive control of stock, upkeep, and manufacturing scheduling. Those methods analyze historic patterns and real-time stipulations to optimize useful resource allocation and reduce prices whilst keeping up provider ranges.

Complicated Meeting Applied sciences

Innovation in meeting applied sciences is enabling extra subtle integration of aluminium profiles into complicated methods. Structural bonding applied sciences supply high-strength joints whilst keeping up the light-weight benefits of aluminium development.

Built-in fastening methods constructed into profile designs do away with the will for separate fasteners whilst offering protected, repeatable connections. Those methods frequently allow fast meeting and disassembly for packages requiring upkeep accessibility or modular development approaches.

Good connection methods incorporate sensors or digital parts that allow tracking of joint integrity, load stipulations, or environmental components. Those clever connections supply treasured information for upkeep making plans and device optimization.

Long run Generation Tendencies

Rising applied sciences promise to additional change into aluminium profiling within the coming years. Quantum computing packages would possibly allow unparalleled optimization of alloy compositions and task parameters via research of complicated subject material interactions.

Biotechnology packages are exploring bio-inspired floor remedies and alloy compositions that would supply self-healing homes or adaptive traits. Those applied sciences may just allow profiles that routinely modify their homes in line with environmental stipulations.

Complicated recycling applied sciences are being advanced that would allow whole separation and restoration of alloying parts, growing actually round subject material flows that deal with top rate alloy efficiency traits via more than one recycling cycles.

The tempo of innovation in aluminium profiling continues to boost up, pushed by way of the convergence of more than one era domain names and the expanding sophistication of shopper necessities. Those inventions don’t seem to be simplest making improvements to the efficiency and functions of aluminium profiles but in addition increasing their applicability into new markets and packages up to now ruled by way of different fabrics and production approaches.