Trendy HVAC techniques depend closely on exact regulate and energy-efficient operation, and variable velocity drives (VSDs) play a the most important function in turning in that efficiency. Putting in place an HVAC force accurately is not only about getting it to paintings—it’s about making sure optimum potency, long-term reliability, and compliance with construction rules. One of the well-liked drives in the United Kingdom marketplace for HVAC programs is the Danfoss FC102, identified for its flexibility and energy-saving options. On this weblog, we stroll you via the way to accurately arrange a variable velocity force just like the Danfoss FC102, with guidelines that practice widely to an identical VSDs and Danfoss inverters.

What Are the Preliminary Assessments Prior to Setup?

Prior to beginning the configuration of any force, it’s crucial to hold out some preliminary website online and gear tests. Those lend a hand save you expensive errors and make sure a easy setup. First, check up on the force bodily for any indicators of wear, particularly if it’s simply been delivered. Verify that the force type, energy ranking, and voltage elegance fit the necessities of your HVAC gadget. As an example, the Danfoss FC102 is to be had in a couple of energy sizes, so it’s necessary to choose the one who aligns with the motor’s specs.

Be certain that the force is fixed in an acceptable enclosure, particularly in HVAC plant rooms that can be humid or dusty. If the surroundings is harsh, an IP66-rated force like this one is also vital. Good enough spacing and cooling across the force should even be seen as consistent with the producer’s tips.

How Will have to the Electric Wiring Be Completed?

Right kind electric set up is important. Get started through disconnecting the mains provide to steer clear of any electric hazards. Then, attach the incoming energy provide to the proper terminals, most often marked L1, L2, and L3 for three-phase drives. The motor connections must pass to U, V, and W terminals. It’s beneficial to make use of shielded cables for each enter and output connections to minimise electromagnetic interference, in particular vital in HVAC techniques inside business structures. Don’t fail to remember to glue the earth cables correctly. The force’s grounding should be sound to give protection to in opposition to surges and make sure protection compliance.

What Parameters Will have to Be Set First?

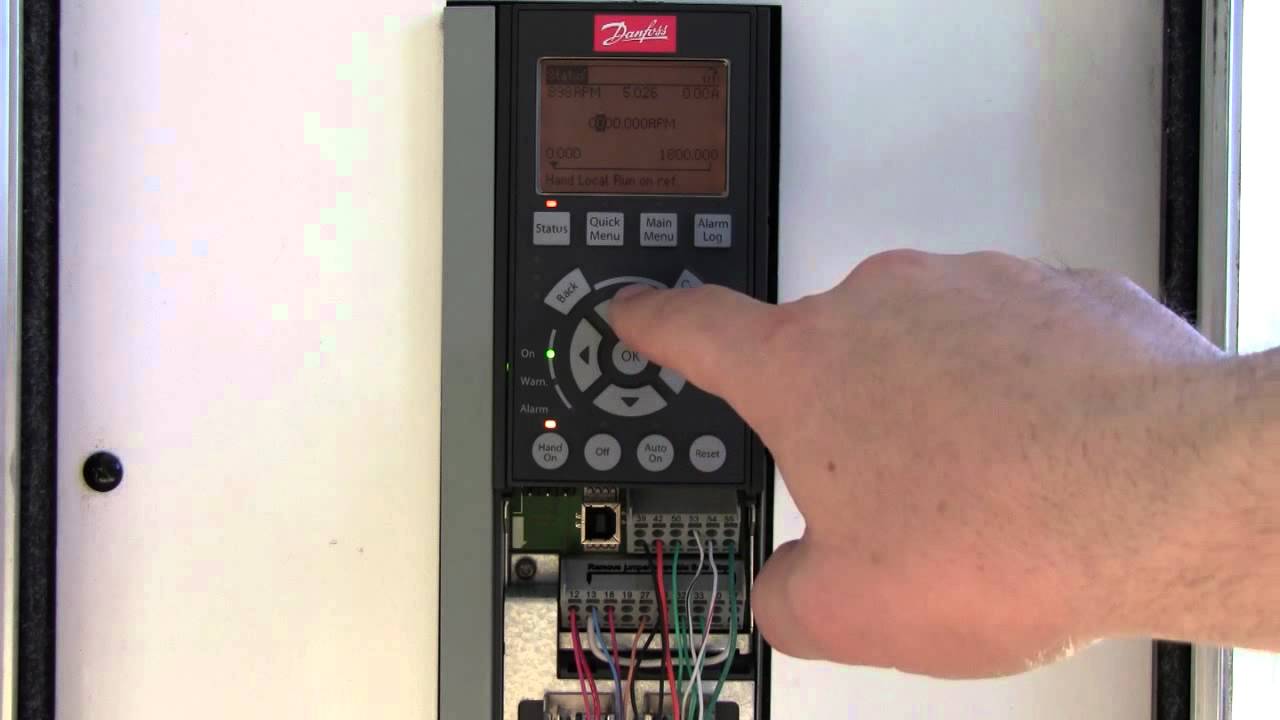

As soon as the force is powered up, start through appearing a manufacturing unit reset to make sure no residual settings from earlier configurations intervene along with your setup. Maximum drives have a handy guide a rough setup menu or wizard—employ this to configure the fundamental parameters.

Key parameters first of all come with:

- Motor voltage, present, and frequency: Those must fit the motor’s nameplate.

- Motor regulate kind: Make a choice from V/f (volts consistent with hertz) or sensorless vector regulate, relying for your HVAC software.

- Ramp-up and ramp-down instances: Those impact how briefly the motor reaches working velocity or stops.

- Minimal and most frequency: This defines the operational limits of your fan or pump.

With the Danfoss inverter collection, together with the FC102, those values can also be simply adjusted by way of the native regulate panel or instrument interface.

How Do You Configure Inputs and Outputs?

Virtual and analogue inputs and outputs are the most important for speaking with exterior regulate techniques like BMS (Construction Control Techniques). Arrange the virtual inputs for instructions akin to get started/forestall or path alternate. For HVAC programs, an analogue enter is regularly used for velocity reference, usually from a 0-10V or 4-20mA sign generated through a thermostat or power sensor. The analogue output can also be configured to relay comments akin to output frequency or motor present, permitting your BMS to watch the force’s efficiency in real-time. Make sure that all I/O connections are correctly mapped within the force’s instrument and examined for accuracy.

What About PID Keep watch over in HVAC Techniques?

In lots of HVAC techniques—particularly the ones involving temperature or power law—PID (Proportional-Integral-Spinoff) regulate is the most important. It allows the force to routinely regulate motor velocity in keeping with a setpoint, like room temperature or duct power. To arrange PID:

- Enter your setpoint supply (both fastened or from an analogue enter).

- Set the comments sign supply (most often from a sensor).

- Track your P, I, and D values. Get started with producer defaults and regulate step by step for optimum reaction with out oscillations or delays.

The Danfoss FC102 has a integrated PID controller, making it particularly fitted to programs akin to variable air quantity (VAV) techniques or chilled water pumps.

How Do You Take a look at and Fee the Force?

Prior to commissioning, double-check all electric connections and parameter settings. Run the motor in handbook mode first to watch fundamental operation. Steadily build up the velocity to make sure easy acceleration and deceleration. Then, transfer to automated mode the usage of your regulate enter, akin to a BMS sign. Apply the force’s reaction to adjustments in setpoint or load. Take a look at key signs at the show—frequency, present, temperature, and fault codes.

Report all settings, particularly if the gadget will likely be passed over to a amenities control group. Label wiring and take care of a report of all parameter adjustments for long run servicing.

What Faults Will have to You Glance Out For?

Even with a a hit setup, problems can stand up. Not unusual faults come with:

- Overcurrent or overload faults: Generally led to through unsuitable motor knowledge or a jammed load.

- Undervoltage: Can point out a susceptible provide or free wiring.

- Overtemperature: Be certain that the force has correct air flow and isn’t operating past its rated capability.

Maximum drives supply diagnostic gear and fault logs, making troubleshooting easy. The Danfoss inverter platform additionally helps far off tracking and diagnostics, which generally is a large receive advantages for greater websites.

How Can You Optimise the Force for Power Potency?

In any case, after the force is operational, believe fine-tuning it for calories financial savings. Many HVAC drives, together with the Danfoss FC102, be offering calories optimisation modes. Those can scale back motor calories intake right through partial load stipulations.

You’ll additionally agenda force operation by way of integrated timers or exterior controllers, restricting run time to when wanted. Observe calories utilization incessantly the usage of the force’s integrated calories meter and regulate your technique accordingly.

Ultimate Ideas

Putting in place a variable velocity force just like the Danfoss FC102 accurately is very important for a competent and effective HVAC gadget. Whilst the method would possibly appear technical, following a structured way—from set up to commissioning and optimisation—guarantees the force works in cohesion along with your broader construction techniques. For engineers and amenities managers in the United Kingdom, making an investment the time to configure the force correctly will pay off in calories financial savings, diminished downtime, and more uncomplicated long-term upkeep.